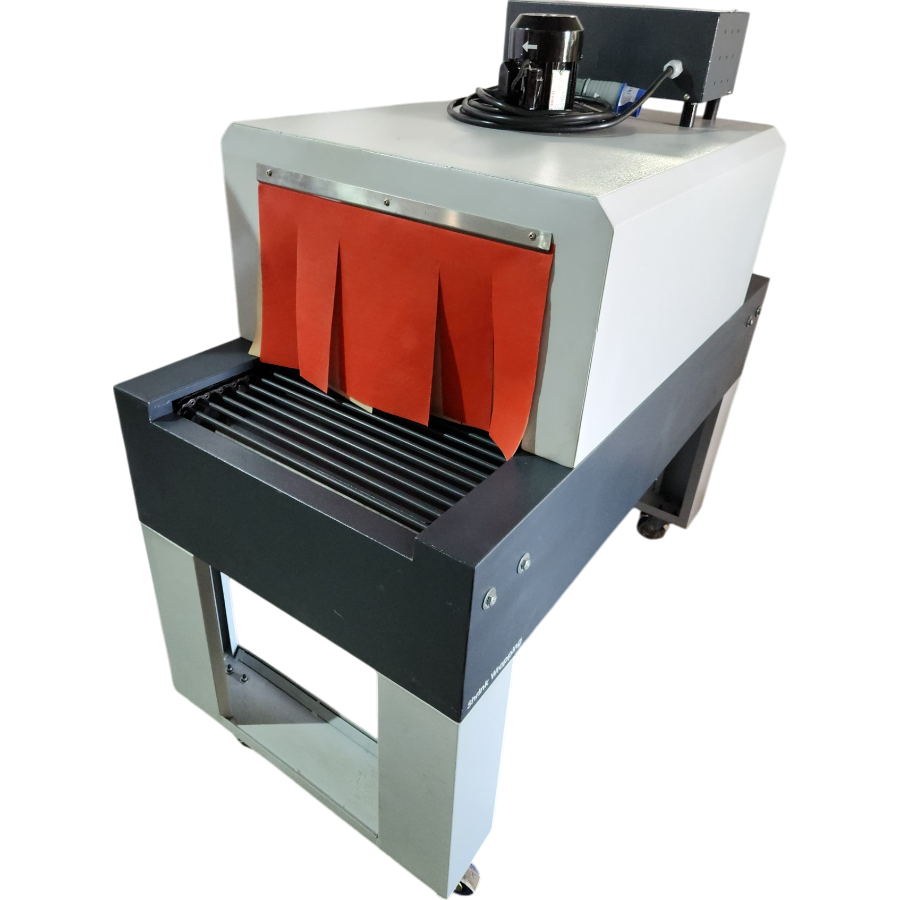

In the field of packaging,shrink tunnels are widely used to tighten the outer shrink films/sleeves around the plastic containers as they pass through the heated chamber through a conveyor. Offering clean wrinkle-less wrapping, the shrink sleeves take the shape of your products while passing through the chamber like foodstuff, beverage, pharmacy, video disc, hardware, cosmetics, electronic appliances, books, toys etc. They are widely recommended for:

Brand Labels like in case of Bournvita Containers

Transparent Shrink Sleeves/Films for top to bottom covering with shrink films like in case of pharmaceuticals to prevent adulteration

In case of Agarbattis, Earthen Lamps (Diyas), these products can be bundled together and fed into the machine's conveyor belt for clean outer packaging.

Next Packaging's Semi-Automatic Shrink tunnels guarantee you the most efficient solution in this. You can adjust the heat settings and conveyor speed of the shrink tunnel in order to heat a shrink film properly. As the heat is applied to the shrink film, the film gets conformed to the product tightly. Shrink tunnels are a great option for medium to large scale production environments to increase production while offering a consistent shrink rate to all products. These ergonomically designed tunnels guarantee an impeccable result, with specific focus on the end customer. We also offer cooling blower at the exit end, in case of need, at an additional cost. With temperature and conveyor belt speed controls, the machine can be fine-tuned to offer the perfect heat exposure.

Working:

As different products and materials require varied heat exposure, it's important to adjust the temperature and conveyor speed in the first stage. Then, the operator has to manually place the shrink sleeves around the containers and later, feed them onto the conveyor belt one by one to get them packed in an accurate manner. Also, products can be fed vertically as well as horizontally.