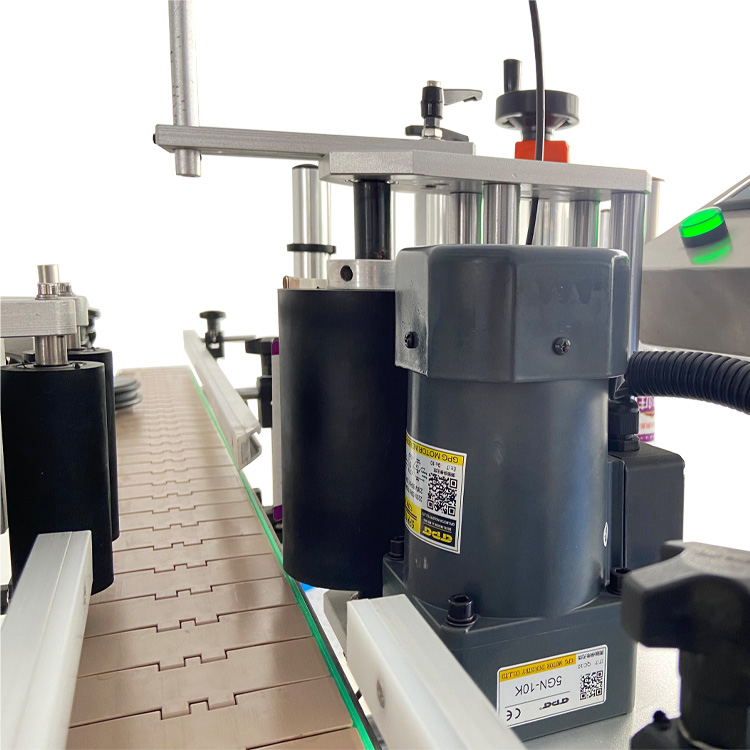

Automatic Front Back Wrap around sticker labeling machine

Automatic Front Back Wrap around sticker labeling machine

SPECIFICATION: 6 Head Automatic SERVO Based Liquid Filling Machine.

1. Product: Oil

2. Container: Plastic Container

3. No of Filling Nozzles: 6

4. Filling volume: 20-600ml

5. Output: 30-40 BPM.

Make of the components used in the machine:

• SENSOR - P&F.

• FRL UNIT - JANATICS

• PNEUMATIC CYLINDER - JANATICS

• ARS SLIDE - HOLMARC

• HMI - WECON

• SERVO MOTOR – WECON (750WATT)

• CONVEYOR MOTOR – BONVERIO

• GEARBOX - BONVERIO

• PLC - WECON

• SOLENOID VALVE - JANATICS

• SLAT CHAIN - S.S.

• VFD - DELTA

• GEAR PUMP - S.S. -316

Container Handling:

Empty bottles are manually placed on Conveyor. The bottles are automatically held under

filling nozzles till the required quantity of product is filled in bottles.

Filling Station:

This is S.S. Pump based filling machine. The product is stored in Hopper. And the product is sucked by the pump during the suction stroke and dispensed into the bottles during the delivery stroke.

During the suction motor gives drive to pump between the tank and the nozzle during which the product stored in the tank is sucked into the pump. This product is subsequently dispensed into the bottle

during the discharge stroke during which the port of Valve Body. Neck Guide are given for holding the bottles while filling.

The quantity of fill depends on the displacement of the pump. You can set the quantity accurately by Control Panel. Level Indicator Sensor is given on the top of Hopper, if the

level of material goes low the Level Indicator will indicate it on panel and machine will stop till the

material is not filled in Hopper.

Benefits:

Technical Specifications :

| Voltage(V/Hz) | Automatic front back sticker labeling |

| Power(W) | 76 mm |

| Printing Speed(pcs/min) | Paper, Film, PE, PP |

| Printing Type | 30 to 300 bpm |

| Net weight(kg) | servo/ stepper |

| Max lines | 250 kg |

| Weight |